Technical requirements for precision machining parts

1. Precision Machining Shaft Parts

1) Dimensional accuracy, the journal is the main surface of shaft parts, which affects the rotation accuracy and the working state of the shaft. The diameter accuracy of the journal is usually IT6 ~ 9 according to its use requirements, and the precision journal can reach IT5.

2) Geometric accuracy, journal geometric accuracy (roundness, cylindricity), generally should be limited to the diameter tolerance point range. When the accuracy of a geometric shape is required to be higher, the allowable tolerance can be specified on the part drawing separately.

3) In The machining position, the accuracy mainly refers to the coaxiality of the matching journal of the assembly transmission parts relative to the supporting journal of the assembly bearing, which is expressed by the radial circular runout of the matching journal to the supporting journal; According to the use requirements, the high precision axis is 0.001 ~ 0.005mm, and the general precision axis is 0.01 ~ 0.03mm. In addition, the coaxiality of the inner cylinder and the perpendicularity of the axial positioning end face and the axis line is required.

4) Surface roughness, according to the different working parts of the surface, there can be different surface roughness values; for example, the surface roughness of the spindle supporting the journal of an ordinary machine tool is RA0.16-0.63um, and the surface roughness of the matching journal is RA0.632.5um. With the increase of the machine running speed and the improvement of precision, The surface roughness of shaft precision machining parts will be smaller and smaller.

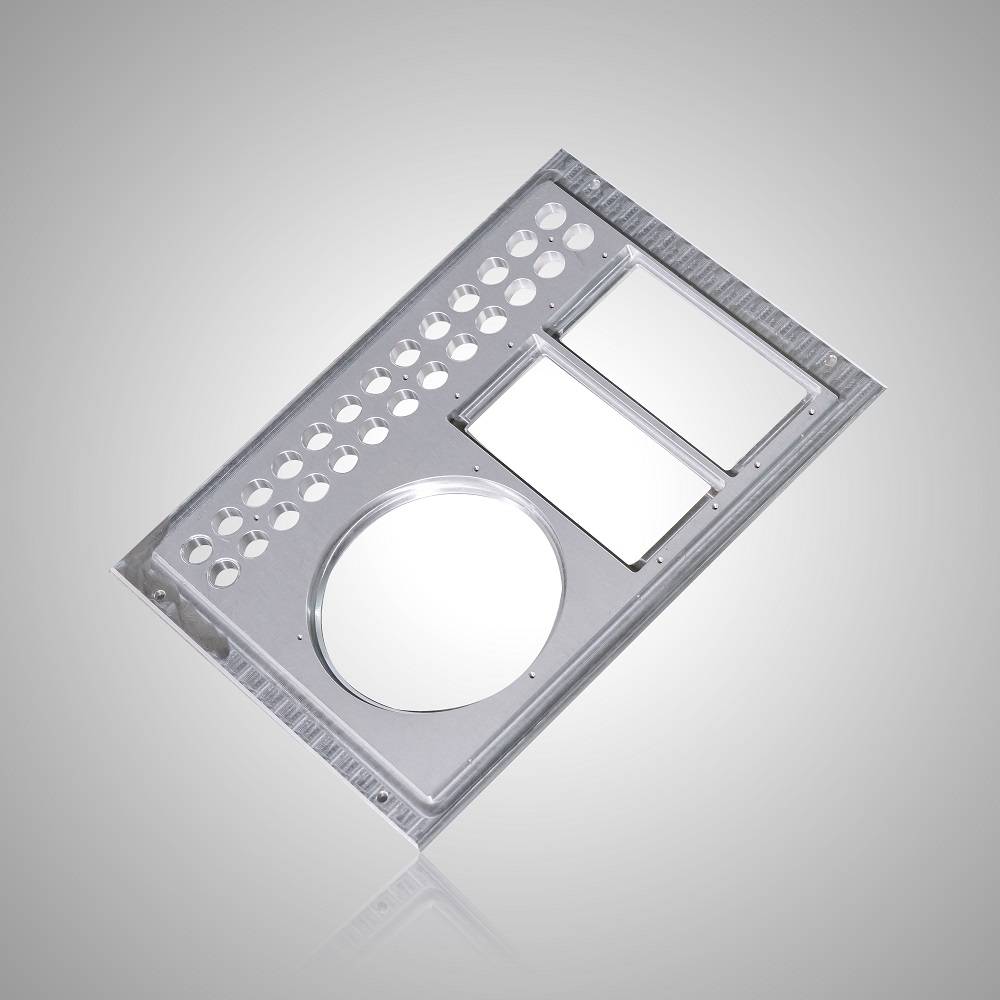

2. Sheet Metal Parts

1) Parallelism and perpendicularity between surfaces.

2) Surface roughness and accuracy.

3) the accuracy, verticality, and hole spacing requirements of the holes on the template.

4) Following the principle of "first hole behind," after the planing pin or milling of the plate, grinding the plane can improve the flatness of the plane and the parallelism of the upper and lower planes and make it easy to ensure the perpendicularity of the hole requirements.

评论

发表评论